Transform Manufacturing with AI-Powered ERP

Eliminate inefficiencies, reduce delays, and gain real-time production insights—all with LENS ERP Suite.

Are manual processes slowing down your production and increasing costs?

Manufacturing businesses face unique challenges that outdated systems can't solve. Our ERP solution addresses these pain points directly.

Frequent production delays leading to missed deadlines

Manual scheduling and production tracking create bottlenecks that cascade into missed delivery dates and unhappy customers.

High operational costs due to inefficiencies

Disconnected systems and manual processes waste valuable resources, driving up labor costs and reducing your profit margins.

Manual data entry errors affecting inventory accuracy

Human errors in data entry lead to inventory discrepancies, causing unexpected stockouts or excess inventory that ties up capital.

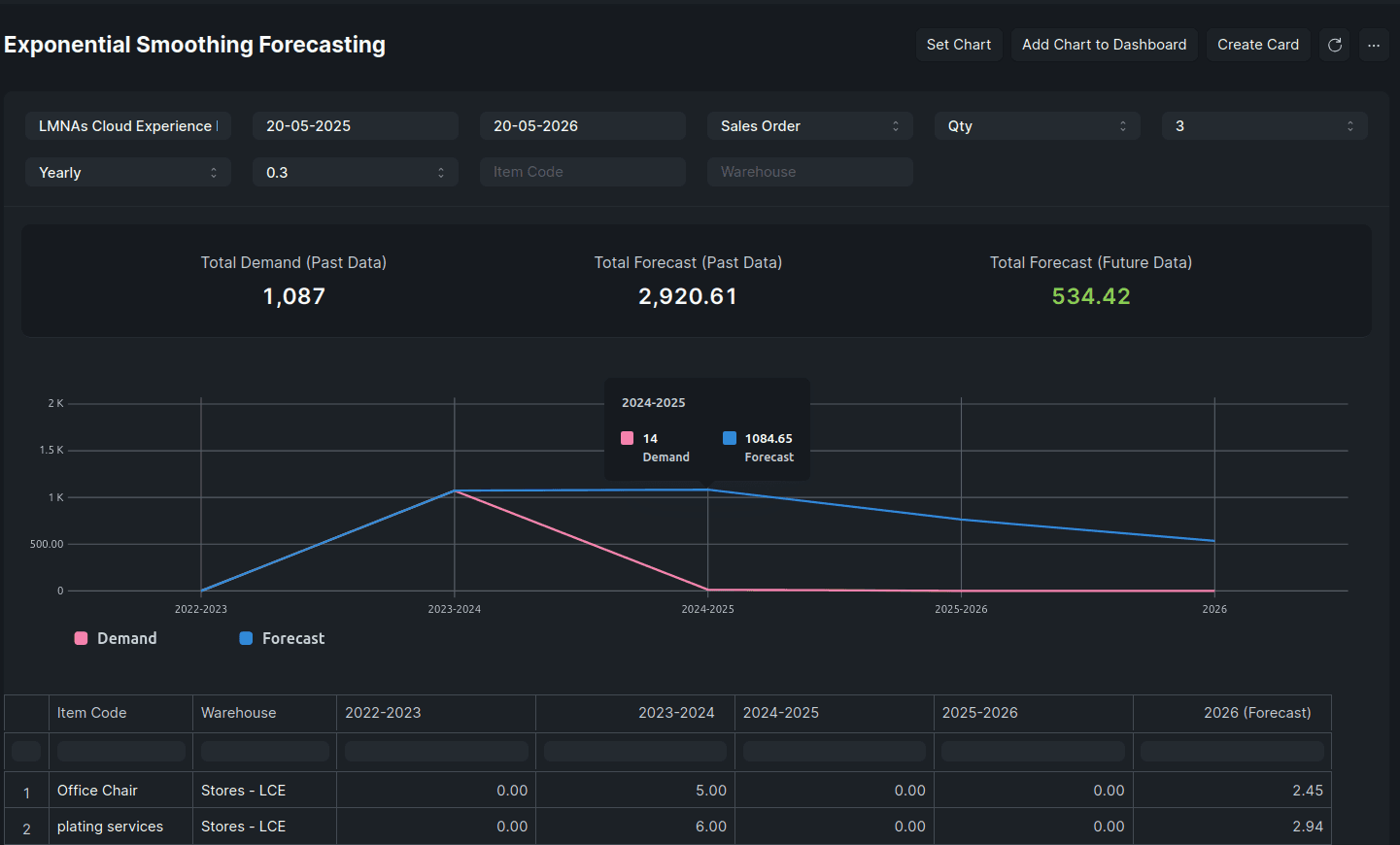

Poor demand forecasting causing overstocking or stockouts

Without accurate forecasting tools, you're forced to guess future demand, leading to either excess inventory costs or missed sales opportunities.

Siloed departments creating communication breakdowns

When your teams can't share information efficiently, critical details fall through the cracks, causing costly mistakes and delays.

Inability to adapt quickly to market changes

Rigid, outdated systems prevent you from pivoting when market conditions change, putting you at a competitive disadvantage.

Ready to solve these manufacturing challenges?

Book a free consultation with our manufacturing ERP specialists

LENS ERP Suite: Streamline Your Manufacturing

Discover how our comprehensive ERP solution can transform your manufacturing operations with these powerful features.

Master Production with AI-Driven Planning

Slash material waste and optimize resource flow with predictive scheduling and intelligent allocation.

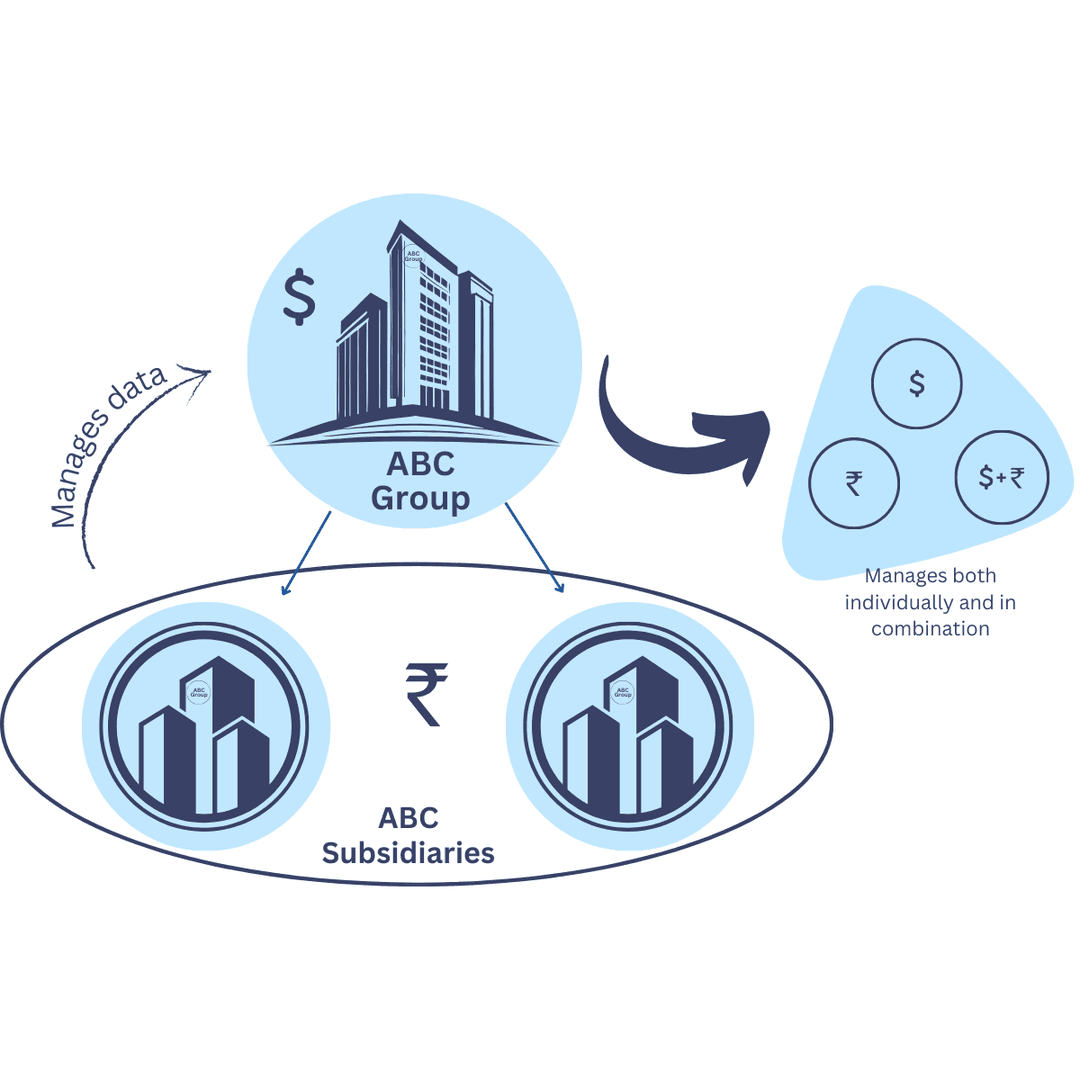

ERP Enabled Accurate, Multi-Currency Financial Integration

Stellar Enterprises implemented a multi-entity ERP setup with real-time currency integration and seamless financial consolidation.

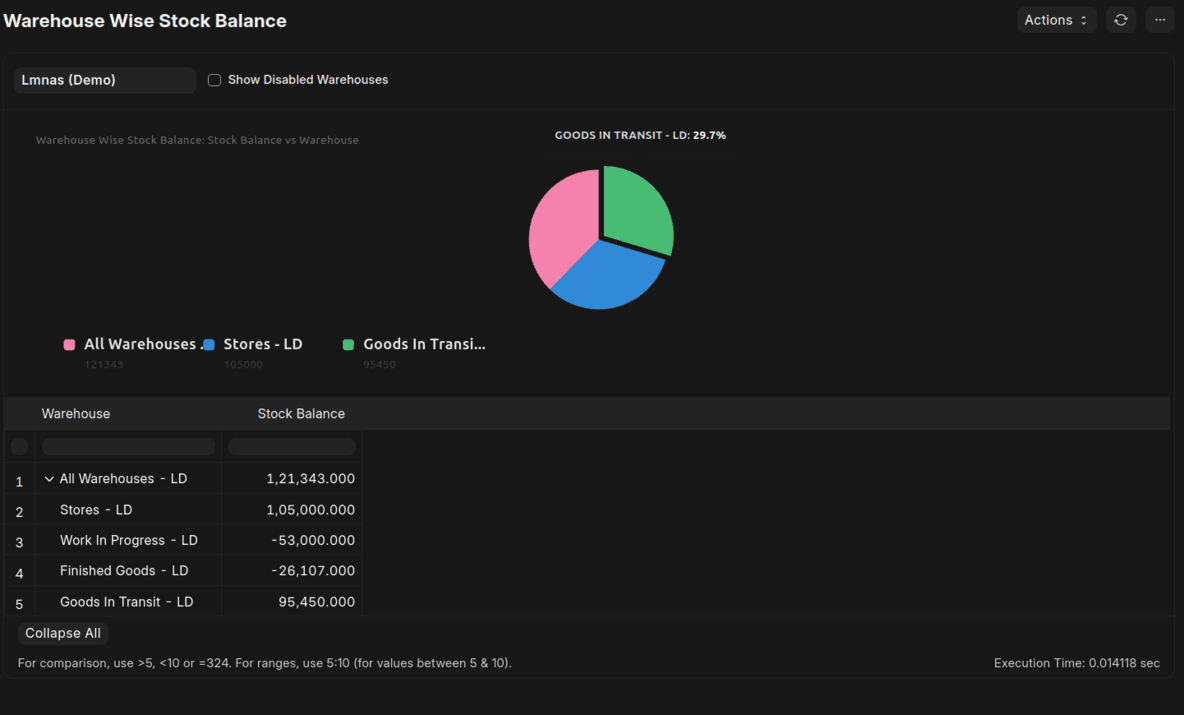

Take Full Control of Your Inventory – in Real Time

Eliminate stockouts and overages with automated tracking, instant visibility, and proactive replenishment.

How NextTrend Stores Improved Turnover and Accuracy with LENS Inventory Management

Discover how LENS helped optimize stock levels, reduce manual effort, and align inventory with real-time retail demand.

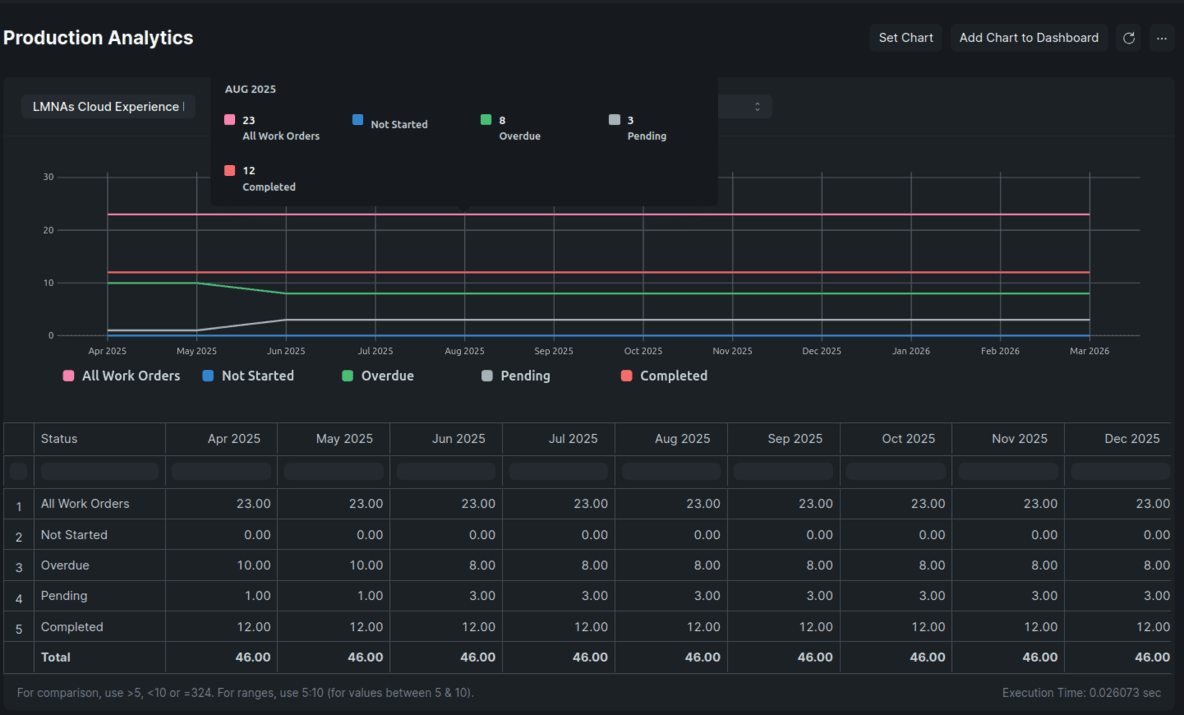

Maximum uptime through intelligent production execution

Prevent costly delays with real-time workflow tracking, automatic bottleneck detection, and intelligent downtime analysis.

How NeoWorks Streamlined Quotation Approvals with LENS ERP

LENS ERP’s automated approval engine helped NeoWorks slash approval delays, boost transparency, and empower smarter decision-making across sales.

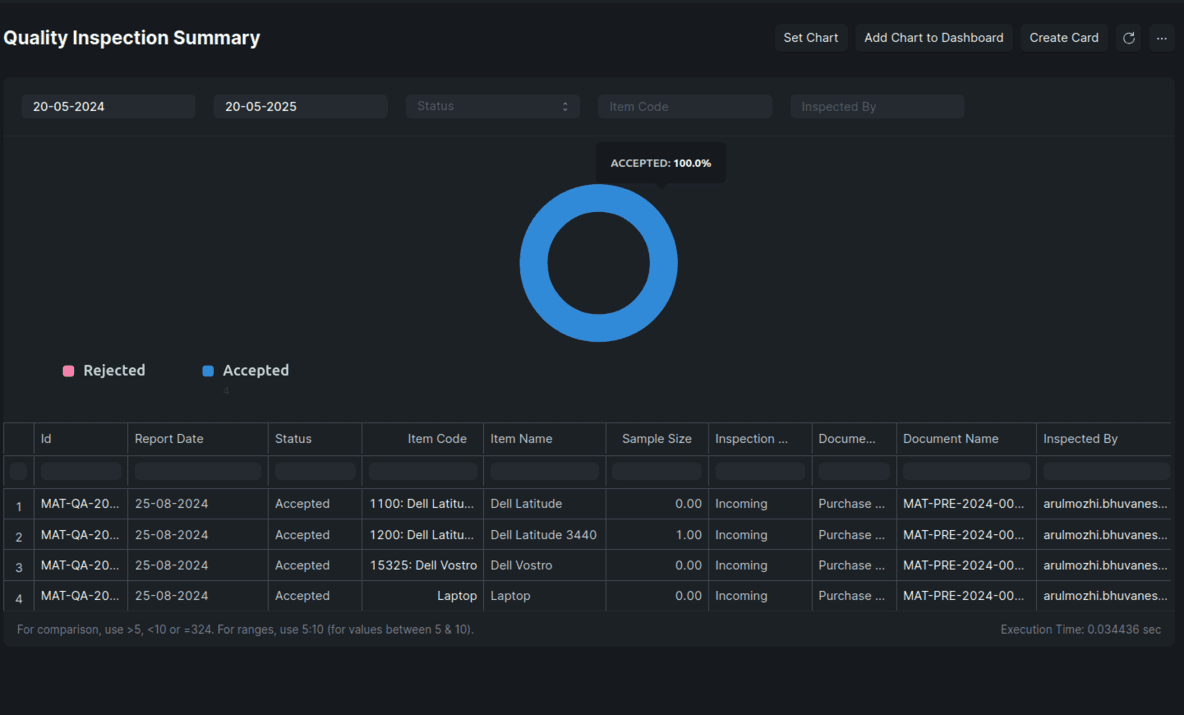

Revolutionize Quality Control with Smart Inspections

Detect defects before they happen with automated inspections, AI-driven anomaly detection, and predictive maintenance.

Auto Supplier Achieves 99.5% Quality Compliance with AI-Powered Inspection

A top-tier auto parts manufacturer slashed defects by 90%, cut rework costs, and exceeded Industry compliance standards.

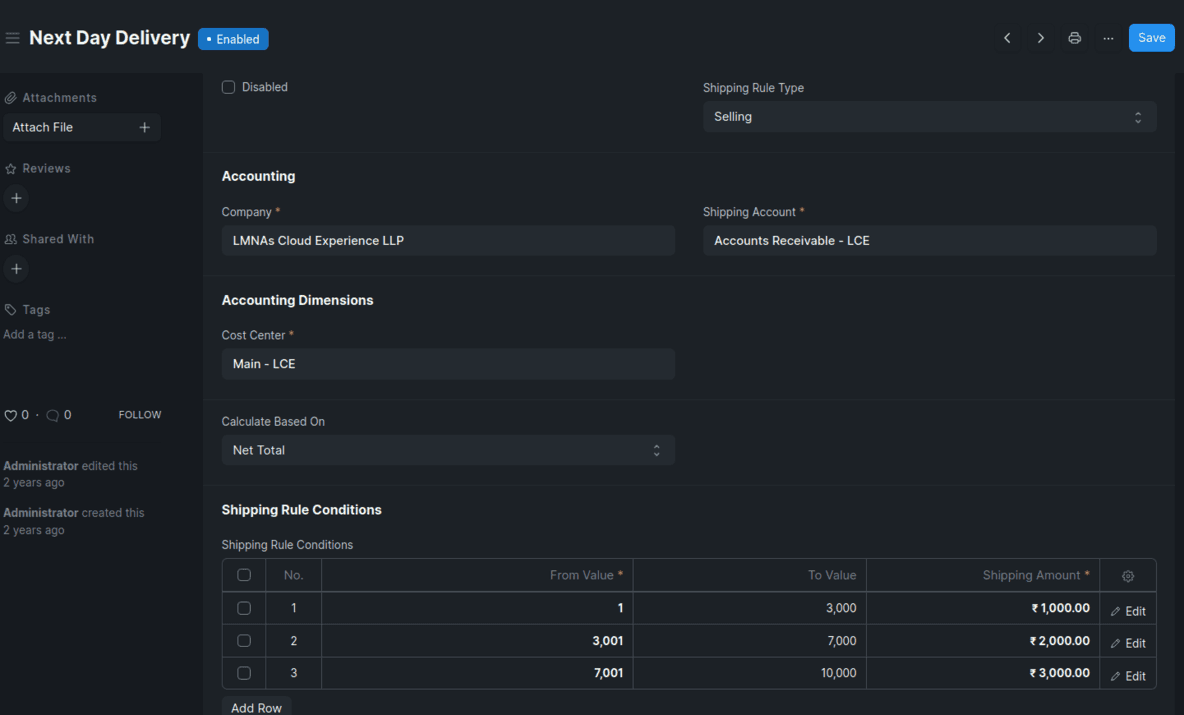

Supercharge Deliveries with AI-Optimized Logistics

Improve delivery times, optimize routes, and reduce costs with intelligent fleet and demand-based scheduling.

Logistics Leader Boosts On-Time Deliveries by 40% with AI Routing

A global distributor streamlined fleet operations, slashed fuel costs, and dramatically improved service reliability.

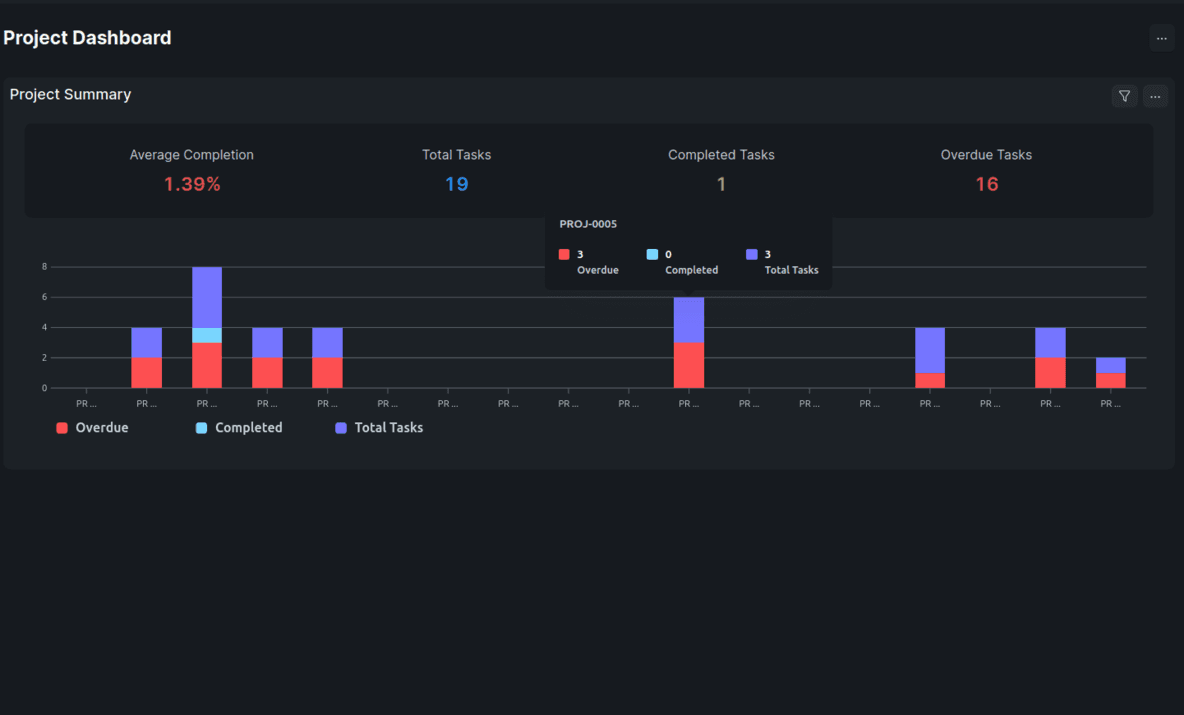

End-to-End Project Management

Seamlessly connect production, inventory, quality, and logistics in one powerful platform for total control.

Industrial Manufacturer Boosts Efficiency by 45% with Connected Workflows

A leading manufacturer integrated all operations, reducing complexity, boosting productivity, and accelerating delivery.

Explore All Features

Bill of Materials (BOM)

Reduce errors in assembly by 60% with structured BOM tracking.

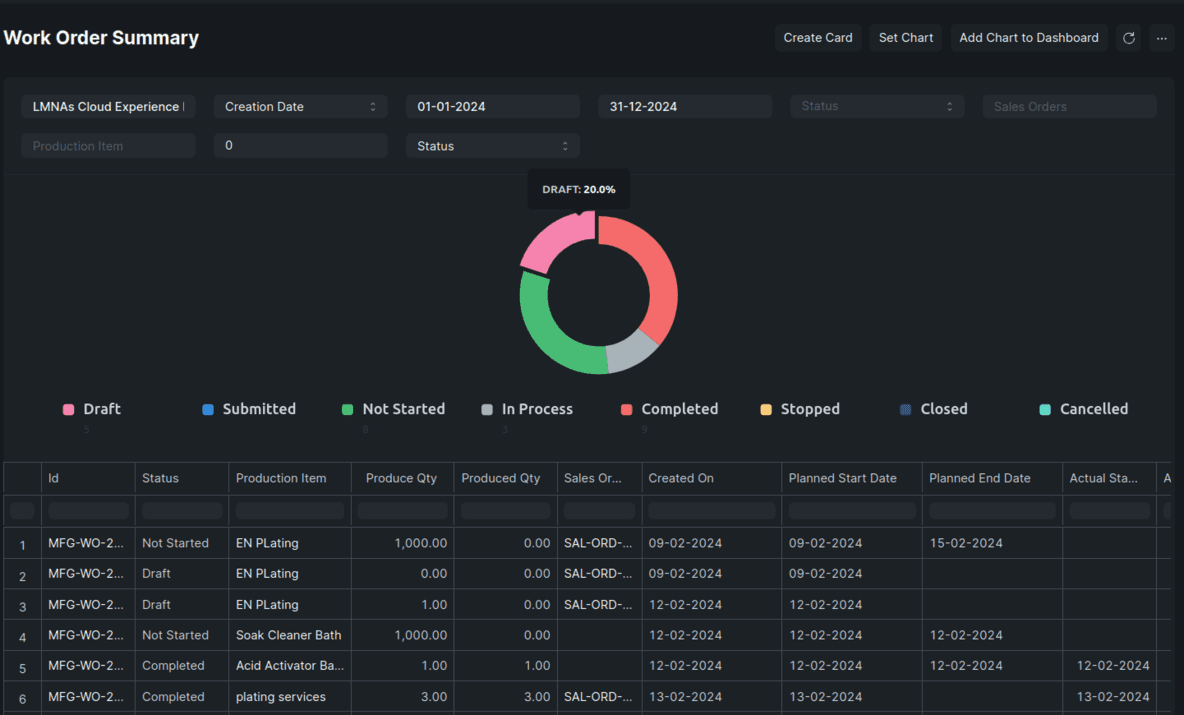

Material Resource Planning (MRP)

Cut procurement delays by 40% with automated planning.

Work Order Management

Increase efficiency by 30% with automated work orders.

Shop Floor Control

Minimize downtime by 35% with real-time monitoring.

Ready to Transform Your Manufacturing Operations?

Join hundreds of manufacturing companies that have streamlined their operations, reduced costs, and increased productivity with LENS ERP Suite.

Schedule a Consultation

Get personalized advice from our ERP experts.

Tailored Assessment

Receive a custom evaluation of your operations.

Live Demo

See LENS ERP Suite in action with your data.

No commitment required. Our experts are ready to help you succeed.

Success Stories

Explore how businesses across different industries achieved breakthrough results with our solutions.

How LENS Centralized Quoting and Sales Across ABC Europe, Asia, and America

LENS broke down operational silos and enabled a seamless sales experience for customers dealing with multi-entity orders.

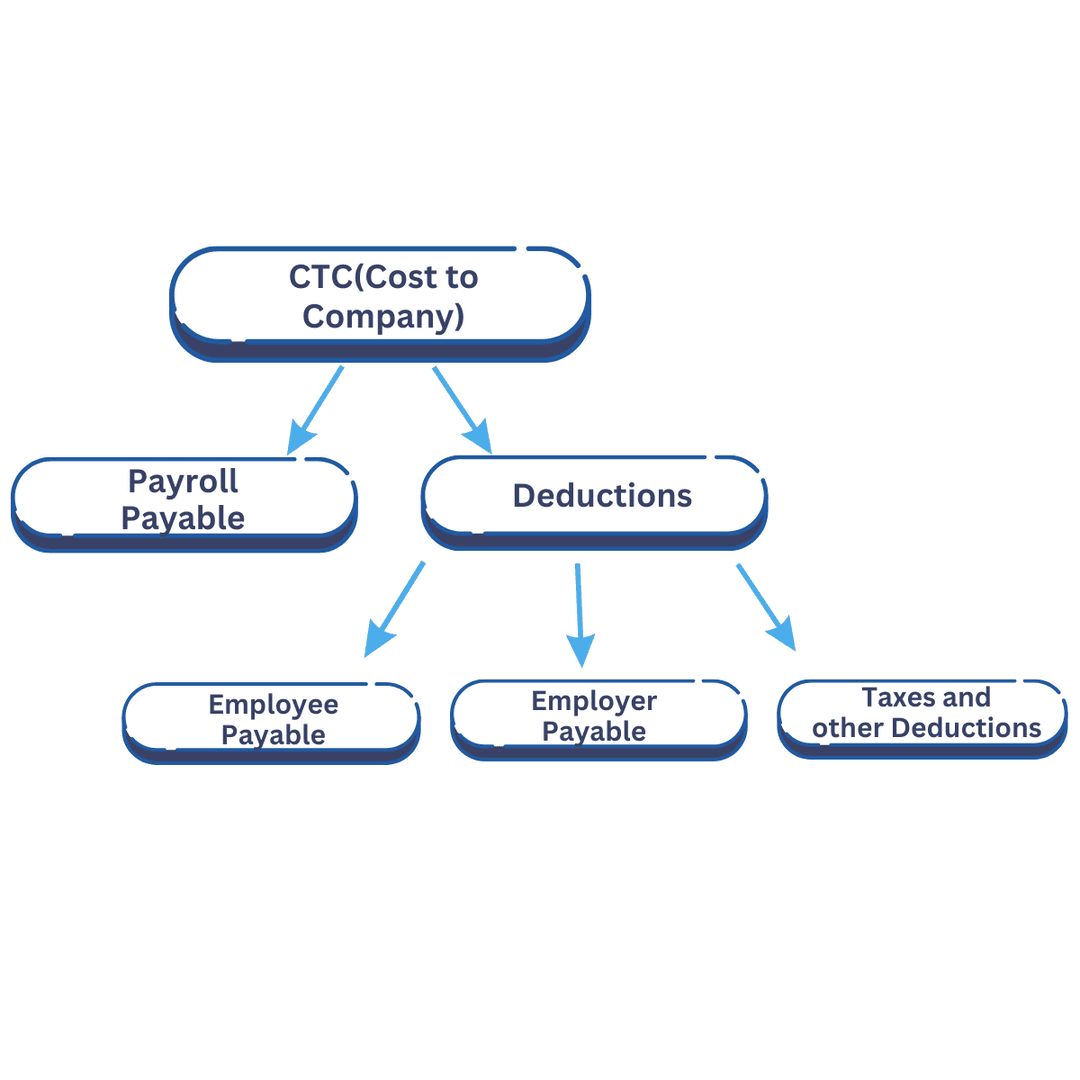

LENS HRMS Automated Statutory Processing and Integrated Accounting

Nova Group embedded compliance into payroll with LENS HRMS—simplifying liabilities, reducing manual work, and improving accuracy.

ERP Enabled Accurate, Multi-Currency Financial Integration

Stellar Enterprises implemented a multi-entity ERP setup with real-time currency integration and seamless financial consolidation.

LENS ERP Delivered Full Operational Clarity and Control

PrecisionWorks adopted LENS ERP for automation, real-time data, and integrated control of inventory, production, and supply chain.